This construct is mostly wood, with papier-mâché for the balloon and the base shell of the gondola, and mesh sandpaper for the deck floor (to mimic the cross-hatched wooden cargo doors on an old deck). It took a couple of nights to make, but a lot of that was walking from basement to top floor scouring the house for possible materials, and waiting for glue to dry…

I did not really start off with any materials in mind. I had bought some of these supplies for something similar a while back, but a lot of these I found around the house as I went – so, just because I used them, doesn’t mean you can’t find something better. I am a starving artist, and also having to use what is handy because I am working after midnight, after most stores have closed. Feel free to substitute – but I have found up-sides to most every improvised material and I will try to elaborate as I go. Materials: 1) Two pre-made papier mache eggs – one large, one small. If you cannot find them pre-made at your local craft store, you can make them by simply layering papier mache around a party balloon. I used the large egg for the balloon, and cut the small egg in half to make the gondola. 2) One large wooden dowel (1 inch diameter), Eight small dowels (1/4 inch diameter or 3/16ths) 3) A spool of wire. I used framer’s hanging wire because I had some handy. 4) Drywall screen. It is a type of mesh used for sanding drywall – a fabric screen coated with abrasive crystals. 5) Some thin wood panels. Modeling stores have them, crafting stores have them. They are typically used for everything from model ships to doll houses. I cut the propellers out of these. 6) A packet of small hardwood spools 7) a packet of hardwood “pickle barrels”, 8 ) a packet of wood beads. 9) Glue – the stronger and harder the bond, the better: Gorilla glue, Tacky glue, Elmer’s glue all… 10) Paint – you’ll probably want to paint yours. I recommend some cheapy apple barrel or comparable acrylic craft paint. For the demo, I am painting everything black, but I will eventually go in with browns and brass colors to finish the job. Tools: 1) Two pen knives / craft knives. I use them for moving small parts, holding other pieces in place, and of course cutting things. 2) A drill, or a drill bit will come in handy. If you have a power drill it does come in handy – but you can make due with a drill bit stuck in the end of a wood dowel. Match the drill bit to the size of your smaller dowels. 3) A pair of shears or tin snips or some really good (or really disposable) scissors. 4) a coping saw or other fine-bladed crafting saw. To Begin: There are a few steps I do not have pictures for (but will correct this when I start the next one. I didn’t at first plan to make a tutorial of this (sorry). 1) The first thing I did was to cut a hole in the top the big papier mache egg. I made the hole just a little bit smaller than the large dowel. I then cut a hole through the other side of the egg, and pushed the dowel through. This is the mast and (possibly) smoke stack… if you want it to be a smoke stack… I won’t stop you. Either way, it is a big pole going through the balloon top to bottom. Make the big mast long enough to protrude from the top, and from the bottom about 3 inches. This mast will also be the main thing holding the gondola onto the balloon. 2) I did the same thing with the small dowels – making holes with my pen knife and poking the dowels in – one long one in the front (foremast), two in the back (for the tail – one straight out the back, one higher up), two on each side (to hold the sails) You can look at the second image down to get the general feel for where I put mine. I made them go deep into the Egg for more strength.

3) To strengthen your masts’ joints with the body, pour glue around where a dowel meets the balloon. Then, with the pen knife, add beads around the mast. This mass of beads and glue will make a nice collar to keep the mast from sliding back and forth, and it will also reinforce the balloon where they meet (see image below).

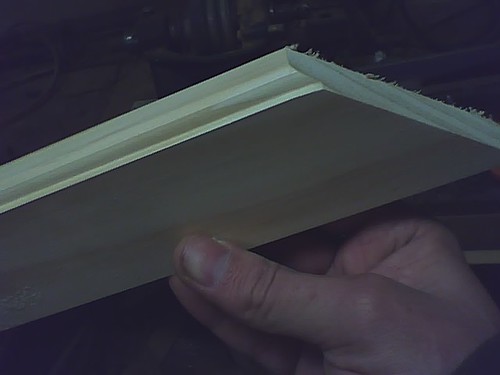

4) For the gondola (above) I cut the smaller egg in half. I also cut a round hole through the bottom where the large mast will just barely pass through (enough to give it a strong bond). 5) I cut a little semi-round divot out of the back and glued a barrel into it (the main boiler). I then glued a barrel in the front to balance it (it also makes a nice wheelhouse). From there, I covered the top with my drywall screen, which a cut with a pair of tin snips. 6) Engine assembly: two short bits of the small dowels on the sides, one as a cross-pipe, and two pickle barrels make the main engine assembly. I drilled holes into the sides of the pickle barrels so the crossbar could be glued in securely.I also drilled holes in the back-ends of the barrels so that I can put my propeller shafts into them. 7) For a touch of added decoration. I also added some wood beads to the top of the assembly. 8 ) The rest is just decor – wood beads cover where the mesh meets the egg, little wood pins add a touch more decor to the deck, a thin shim of wood and some more beads makes a solid walkway to the wheel.

9) For the propellers, I cut two of the small spools in half with a coping saw. I drilled my hole through first – and then I fond that I could just leave the spool to spin on the drill bit while I pressed the blade of the coping saw against it. It worked like a mini-lathe. Follow my example there at your own risk – it may be dangerous. 10) I then carved 4 thin propeller blades from the thin wood slats (using the utility knife) and I glued them to the top of one of the spool halves. Then I glued another spool half on top of the propeller blades, sandwiching them in between. 11) Repeat the above step for a second propeller.

12) I cut the ends off of another spool, and used them as end-caps on a 3-inch piece of a small dowel. Again, I drilled holes in the spool first, so the end caps will go around the shaft. These end caps will allow your propellers to spin freely, without the worry of them falling off.

13) Lots of black acrylic paint. When adding a patina to anything, it is often easier to go black to light, especially when it comes to acrylics. Slather the stuff on – not only will it add strength to your construct, but it will smooth out the surface of the balloon.

14) I cut the sails from the drywall screen (abrasive sheets). I pretty much just held them up to the masts I had made, and cut n small steps until they were just how I wanted them. Then, when the sails were the right size and shape, I tied them to the masts with thin wire. I did not have any thin wire handy, so I unraveled the framer’s hanging wire. I tied in about 4 spots per mast. If it is hard to tie, you can twist the wire instead… that may even be better. 15) For the jib sail, I had to secure some of the thicker wire between the top mast and the foremast, so i could have something to tie the sail onto. You could probably use a really thin dowel for this and have a *much* easier time.

15) With the sails tied on, I poured glue through the sails where they met the masts and cables. The nice thing about having used the mesh – the glue passes right through the holes.

16) I put the propellers onto the shafts I had previously end-capped – make sure the holes through the propeller are big enough to allow for spinning (they should be if your drill bit is the same size as the small dowels). If not, give them another pass with the drill… some glue might have gotten in there, or the pieces might have shifted before drying. 17) If they spin, or if you don’t care if they spin, you can now glue the shafts into the holes at the back of the engine assembly.

18) Done… or for the most part. I have ideas on what color I am going to paint mine – but you know the principle: put paint on a brush, brush paint where you want it – use smaller brushes for details, bigger brushed for bigger areas – ‘not too much more I can tell you there.

I’ll post pictures of mine when I am done. For tonight, I have to let everything finish drying…. then off to the World Steam Expo on Wednesday night/Thursday Morning.